About Siempelkamp ForgeIQ

Partnering with customers to maximize forging profitability through the implementation of the latest technologies and processes.

The forging industry is a globally competitive one. Forging operators in North America can be competing for work with their counterparts in Asia, Europe, South America or the Middle East.

In such an environment, all forging operators must stay current with the latest technologies, continually optimize their workflows, and find every advantage to keep their operations running profitably.

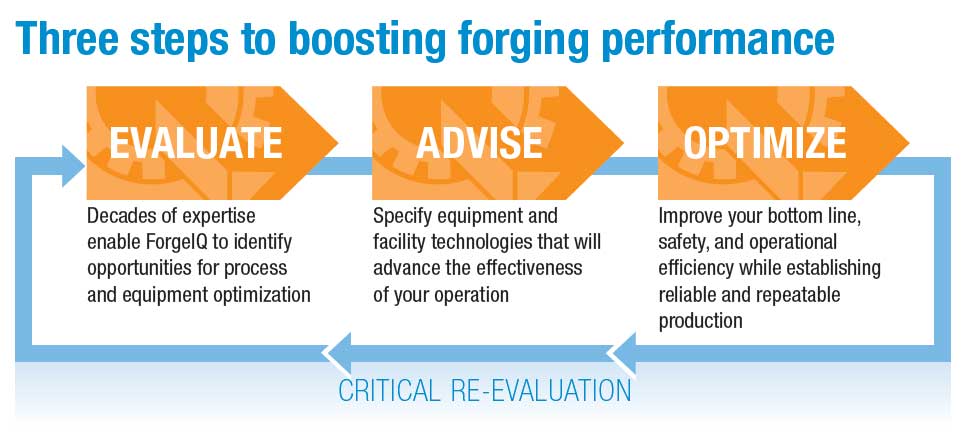

In addition to providing expert field service and repairs, facility modernization and engineering services, maintenance, spare parts, forging equipment and forging consultation, Siempelkamp ForgeIQ becomes your trusted advisor and partner in helping to maximize your profitability and build a world-class forging operation based on the latest technologies.

Siempelkamp ForgeIQ will help you be more of what you need to be when competing in the global marketplace: more reliable, more effective, more operationally efficient, and more profitable.

Siempelkamp ForgeIQ: a powerful partnership

The principals of ForgeIQ have designed, modernized, and installed globally some of the most advanced forging facilities for aerospace structural/engine, energy, and industrial applications. The combined Siempelkamp ForgeIQ brings an unparalleled combination of engineering, repair service, and consulting expertise with the backing and support of Siempelkamp–the world leader in forging presses and ring rolling equipment.

We have decades of experience with everything from field service to the maintenance, repair or optimization of a single forging press or ring rolling press to the full concept, layout and specification of an entire multi-press, multi-flow path facility.

Forging performance reimagined

Siempelkamp ForgeIQ does not provide the same tired solutions based on technologies dating back to the 1900’s. We think dimensionally to incorporate the latest advances to transform our customers’ operations into truly new, optimized, operationally efficient production engines.

We have relationships with the leading machinery suppliers in the industry and can ably assist in the specification of equipment, providing the optimal recommendations for your particular operation.

Because the principals at Siempelkamp ForgeIQ all come from leadership roles with real-life, top-tier forging manufacturers, we know how to focus on real value-add that moves the needle in the areas of safety, operational efficiency, and reliable, repeatable production that in turn improves profitability.

Contact Siempelkamp ForgeIQ to learn how can we help you to reimagine your forging performance.

Siempelkamp ForgeIQ can assist with:

• Facility layout and design

• Flow path optimization

• Equipment specification

• Equipment modernization

—– Electrical controls

—– Hydraulic system

—– Replacement equipment components

—– Additional equipment capabilities

• Forging equipment training

• Complete forging process and heat-treat / quench simulation

• Thermal management

• Finite element analysis (FEA)

• Non-destructive testing (NDT)

• Total Productive Maintenance (TPM)

• Qualification support

• Business strategy and business case evaluation